It will still save your life if done right.

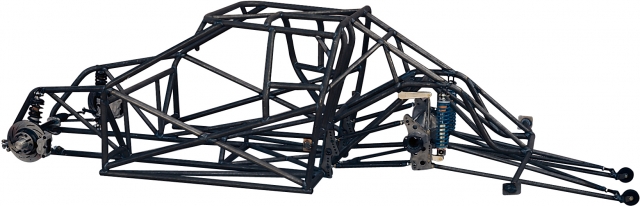

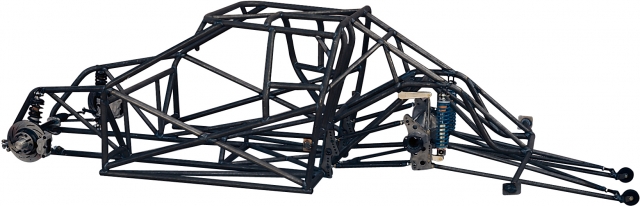

Chromoly vs mild steel chassis.

If it is mild steel then i have to rebuild the whole thing.

In today s chassis it is common to find mild steel erw tubes high strength steels hss such as dom and 4130 chrome moly chromoly and advanced high strength steels ahss like docol tube r8.

So if you run a comp buggy 4130 is the way to go.

One of the never ending topics of conversation is the use of 4130 steel over mild steel in professional drag racing builds.

Chromoloy tubing is made from a family of low alloy steels that contain chromium and molybdenum sae 4130 or 4140 along with the iron carbon and other elements.

Chromoly is slightly heavier than aluminum but the frame can be thinner and has reduced stiffness which provides a smoother ride.

In a trail rig like mine i will be using mild steel and a mig.

Aluminum is the second most commonly used material for bicycle manufacturing.

When cost is a factor as for most of us mild steel is a good choice.

I have a dragster frame and i don t know what it is made of.

If anyone has a viable answer please let me know.

In this short video tim mcamis explains some of the differences between 4130 chromoly and mild steel tubing for use in drag race chassis construction.

It s lighter and stiffer than steel but it s also more brittle and easily damaged.

The chromium adds strength hardenability and a level of corrosion resistance to mild carbon steel though chromoly is not as corrosion resistant as stainless steel.