These resistance heating elements accurately raise the workpiece temperature to the proper temperature before during and after welding complying with recommended preheat interpass and pwht practices.

Ceramic resistance heaters.

The ceramic on the other hand increases its resistance sharply at the curie temperatures of the crystalline components typically 120 degrees celsius and remains below 200 degrees celsius providing a significant safety advantage.

Since we know that the hot water electrical circuit feeds 220 vac to the 16 ampere heating element the resistance of that element is equal to 13 75 ohms.

They are as follows.

We can round that number up to 14 ohms.

Ptc ceramic materials are named for their positive thermal coefficient of resistance i e resistance increases upon heating.

Seen with low quality heaters which use steel ferrules.

In order to find the resistance of the heater element from the above described section we must algebraically modify the formula to read r v a.

While most ceramics have a negative coefficient these materials often barium titanate and lead titanate composites have a highly nonlinear thermal response so that above a composition.

This is an electric heating variant that does not need any type of fuel to function.

Depending on what you are looking for in portable heaters deciding between ceramic heaters or electric heaters is usually an individual choice.

Ceramic heaters also tend to cover a larger area compared to a radiant heater.

Factor 1 cost.

Central furnaces incorporating ceramic block are also available although they are not as common as room heaters.

Besides you can always buy a ceramic heater with a fan for maximum heat spread.

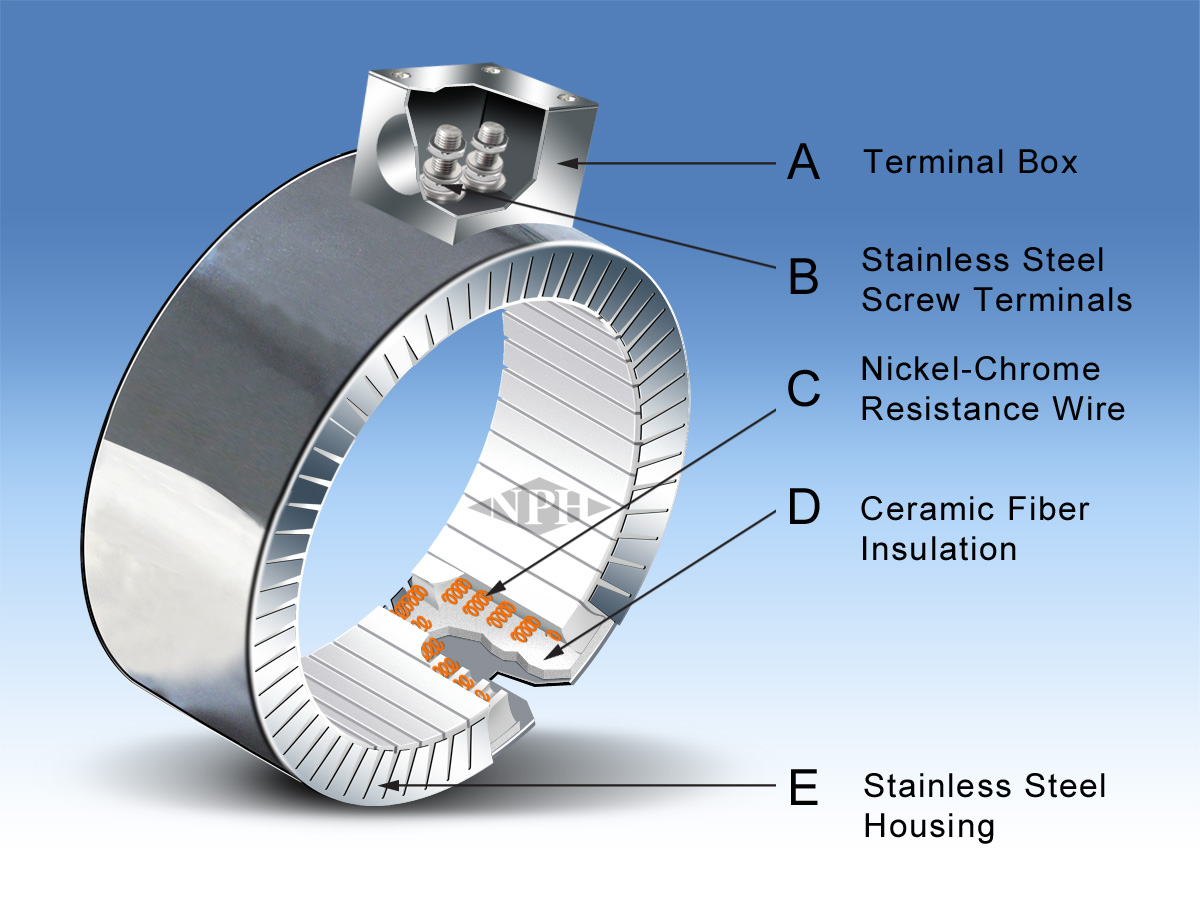

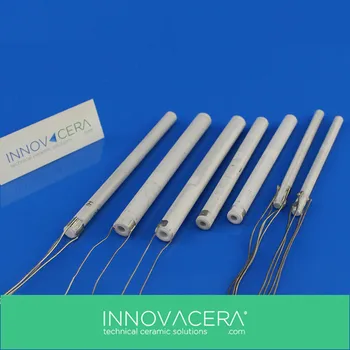

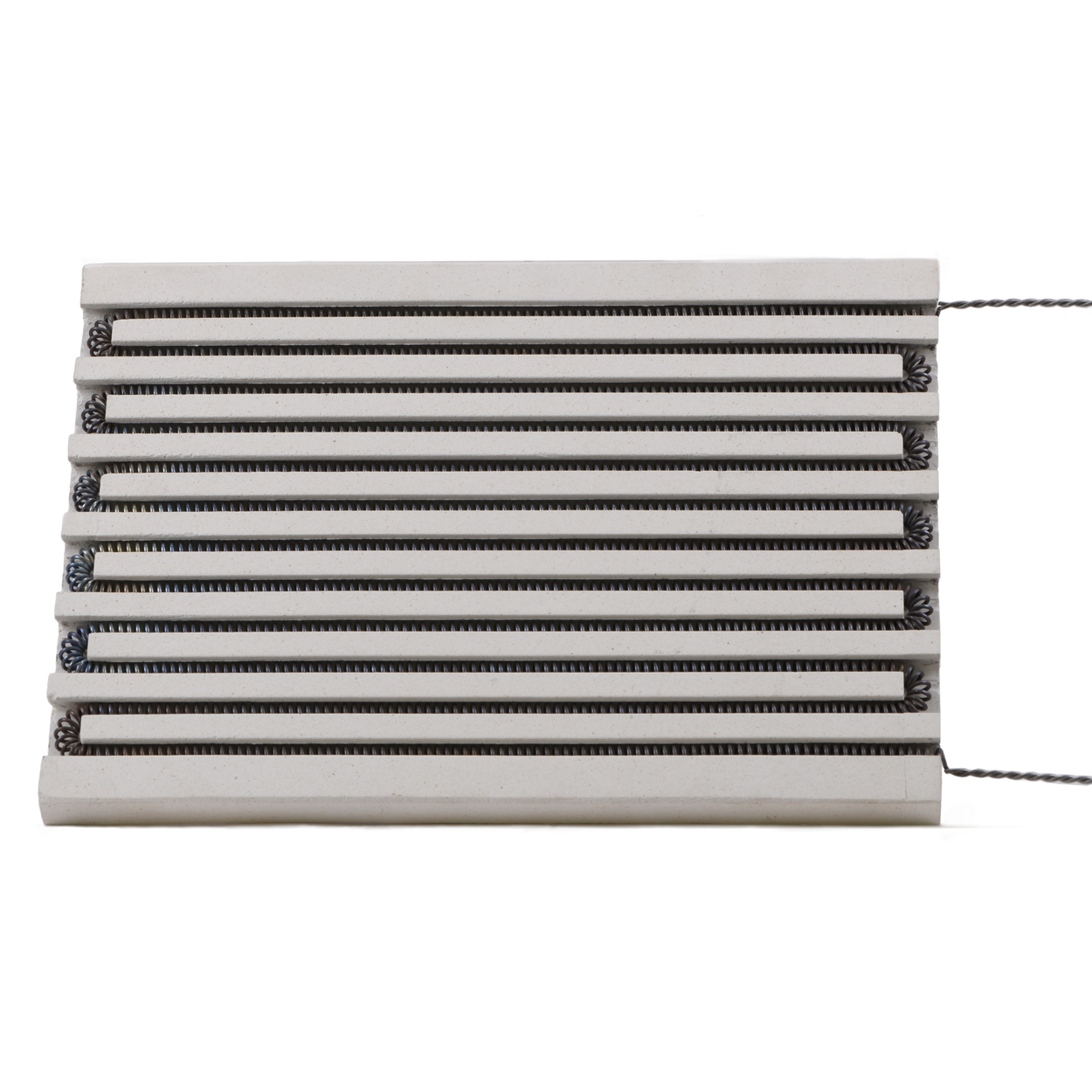

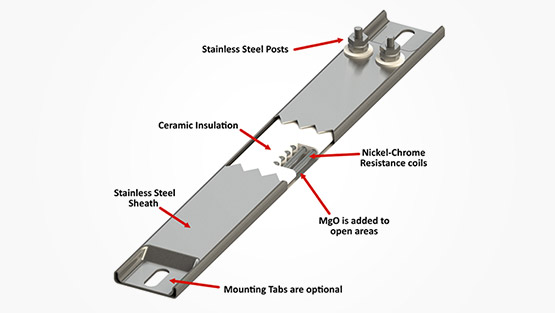

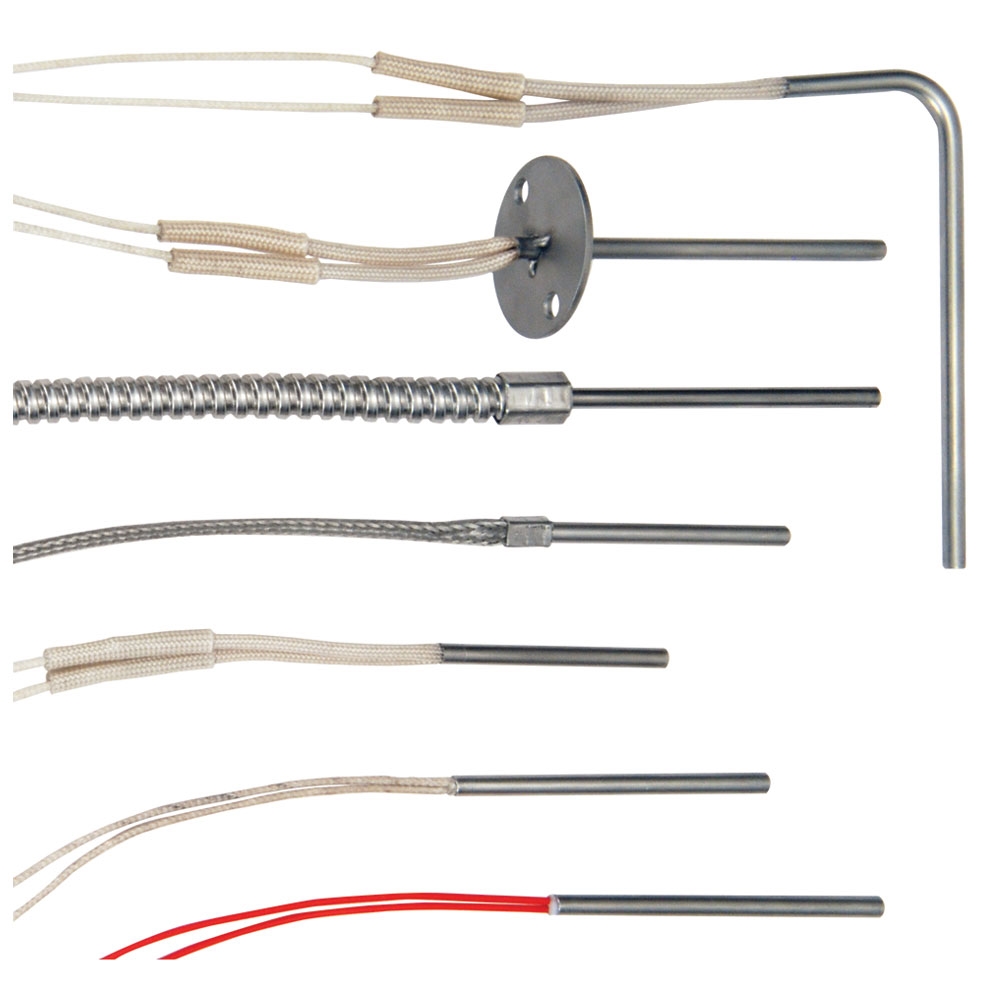

Use of ceramic heater pads resistance heating pads are constructed of ceramic beads strung on nichrome wire.

Ceramic heaters have rheostats that are capable of sending voltage signals when the temperature of the room alters.

There are factors though that can help you determine which heater type best suits your needs.

Storing electrically heated hot water in an insulated storage tank is another thermal storage option.

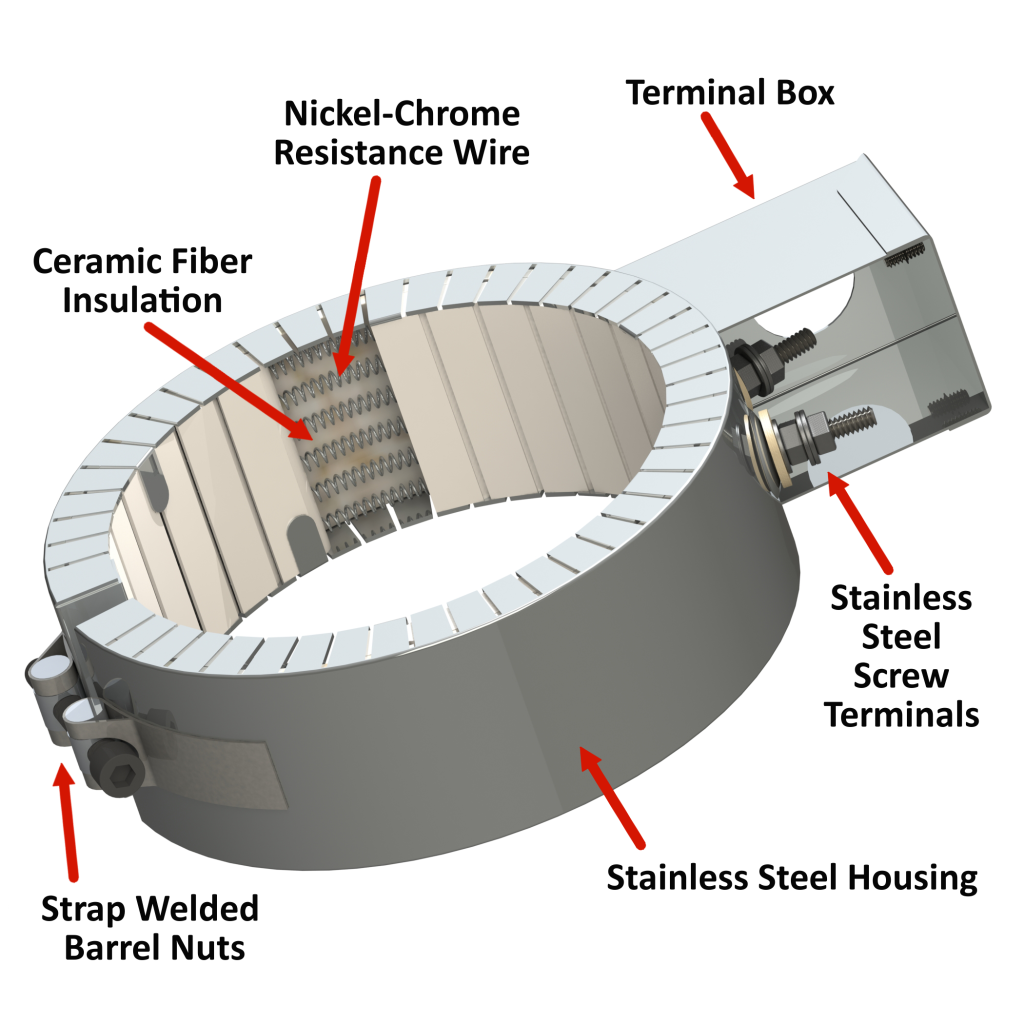

The most common type of electric thermal storage heater is a resistance heater with elements encased in heat storing ceramic.

1 16 of over 1 000 results for heat resistant ceramic glue j b weld 8297 highheat 550 degree epoxy putty stick 2 oz.

Any pipe size or pipe configuration can be covered from the extensive range of fcp heating elements so that the correct amount of heating power can be applied to successfully heat treat the pipe weld or other fabrication.

A helically wound resistance coil made from nickel chrome wire is precisely strung through specially designed ceramic insulating bricks forming a flexible heating mat.

Tempco s style of ceramic insulating bricks offers several benefits including.

Flexible ceramic pads heating elements are manufactured with a range of.

Get it as soon as fri sep 11.

.jpg)